Roll-2-Roll Technologies Adapts Sensing Technology

Copyright © 2016 YTC Media

STILLWATER, OK — In September 2015, Roll-2-Roll Technologies released the ARIS Web Guiding System. ARIS automatically adapts to any materials, requires no set-up, calibration or other manual adjustment operation, and can now be experienced in line, contrast and center guiding.

One sensor can now handle any web guiding. In line detection mode, the sensor can handle a solid or intermittent line, or a line that is adjacent or crossed by a pattern.

Along with the line guiding features, ARIS features two innovative developments in lateral guide technology to sense better and control material.

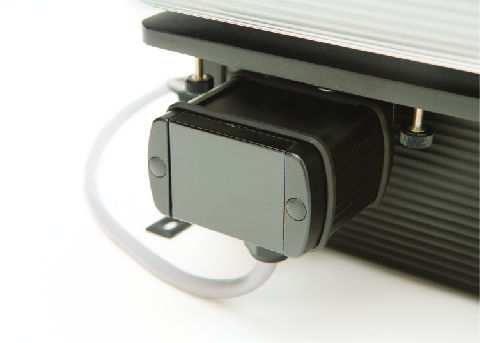

The first feature is the patented material agnostic sensor technology, which is unaffected by changes in materials and environmental conditions, such as ambient light, sound vibrations, or ringing.

This sensor can detect and adapt to any non-porous materials, nonwovens, or transparent materials without time wasting setups or calibrations. The second feature is a patented adaptive control algorithm, which immediately corrects after disturbances, splices, or changes in the material. Our sensor eliminates time-consuming initial setups, sensor and controller calibrations and other manual adjustments, saving you time and money.

These technologies were developed at Oklahoma State University (OSU) based on research and development funded by the National Science Foundation and Oklahoma Center for Advancement of Science and Technology. The material agnostic sensor has a sensing resolution of 63.5 micrometers with a sensing range of 16 or 48 mm.

The sensor provides a true absolute lateral position of the material irrespective of the materials porosity and opacity, hence suitable for many converting applications. The web guiding system is equipped with a high precision and high dynamic response actuator that can position the web within a 10-micron resolution and a max linear speed of 130 mm/sec.

This high precision, adaptive, material agnostic technology is reported to save a lot of time, reduce waste and make the process efficient for flexible packaging converters and label printers.